We are Manufacturer, Supplier, Exporter, Dealer, Services Provider of Easy Lock Systems from Satara, Maharashtra, India.

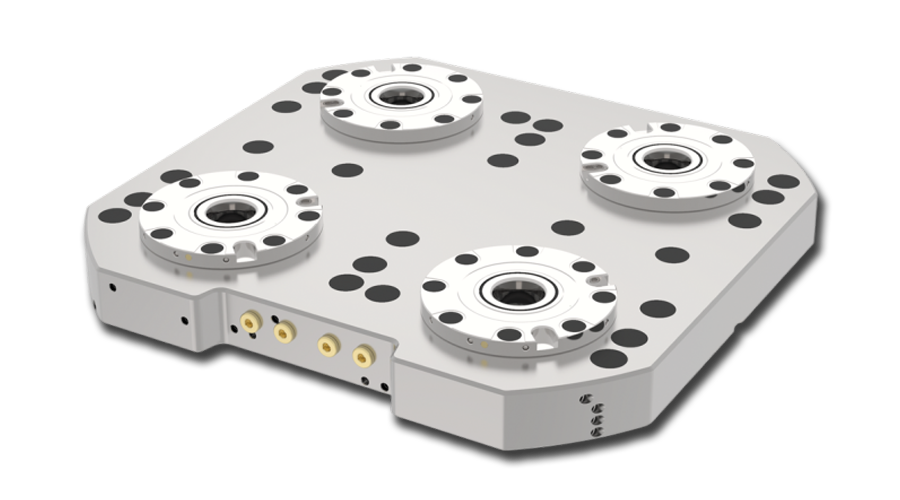

Looking to realize the full benefits of lean manufacturing? Then you need the one system that puts it all together, so you can put it all together…and that's Easy lock. Easy lock is the industry's most popular quick-change, fixturing-flexible mounting system that can be configured to create lean-optimized solutions for your most demanding needs.

Quickly and Accurately Locate and Lock Fixture.

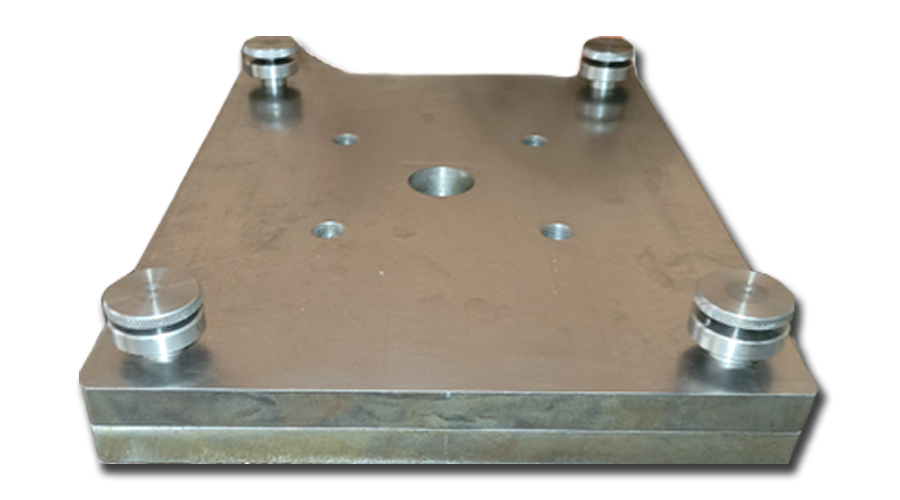

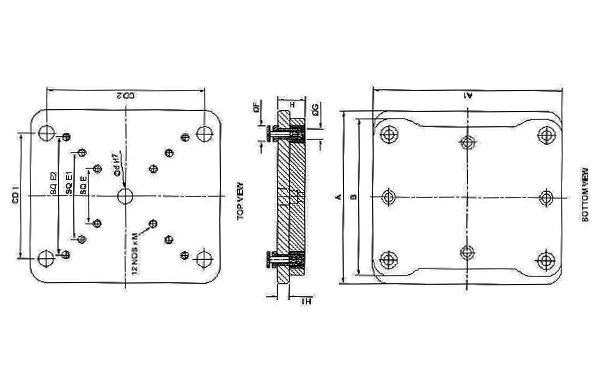

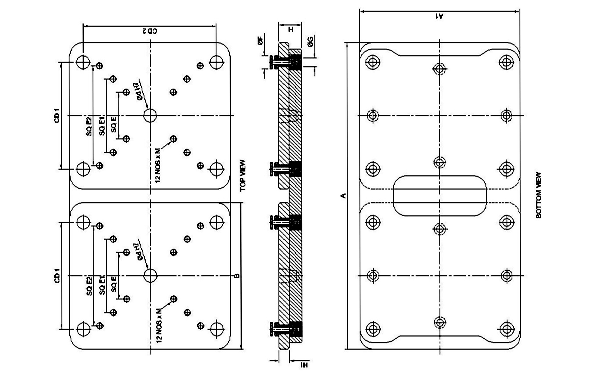

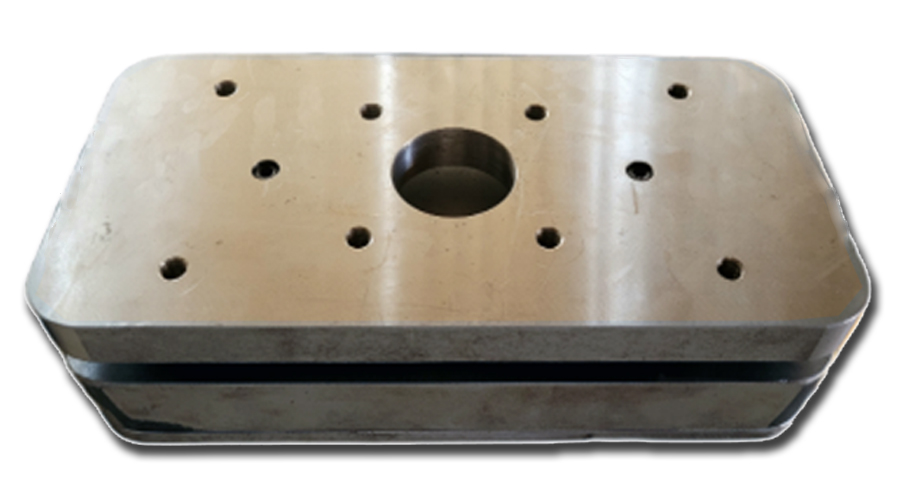

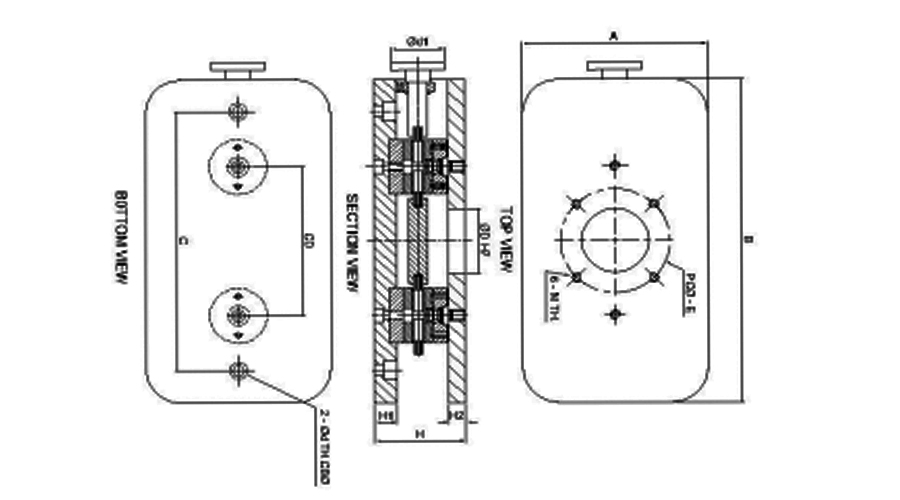

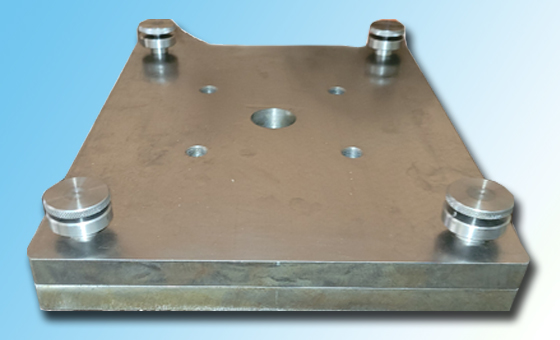

The Easy lock Mounting System is designed to speed the accurate locating and locking of fixture plates to subplates.

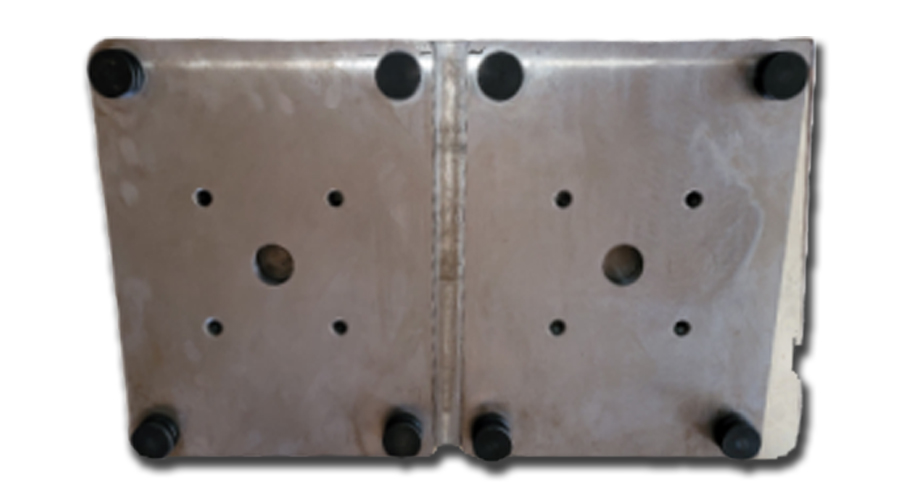

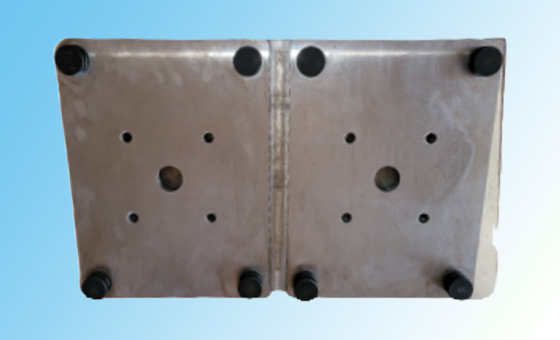

Locating Shank, sub plate and fixture plate. Using the Easy Lock Systems is a simple process: Install a subplate on your machine table; add your fixture plate with locating liner bushings; then insert locating shanks through the liners and into the receiver bushings to provide accurate location. With rotation of 3 to 3 turns of the button screw in each of the locating shanks provides positive holding force. It is recommended that the use of the Easy lock Mounting System for locating and clamping of fixture plates be incorporated in a systematic process. All fixture plates should have two locating points positioned as far apart as possible.

The Easy lock Mounting System provides a method of quickly and accurately locating fixtures onto machine tables. Easy lock provides single minute exchange of fixtures. Fixtures can often be exchanged in less than a minute and with position repeatability of ±0.02mm.

Fixtures can be exchanged between different machines when both are using the Easy Lock Systems.