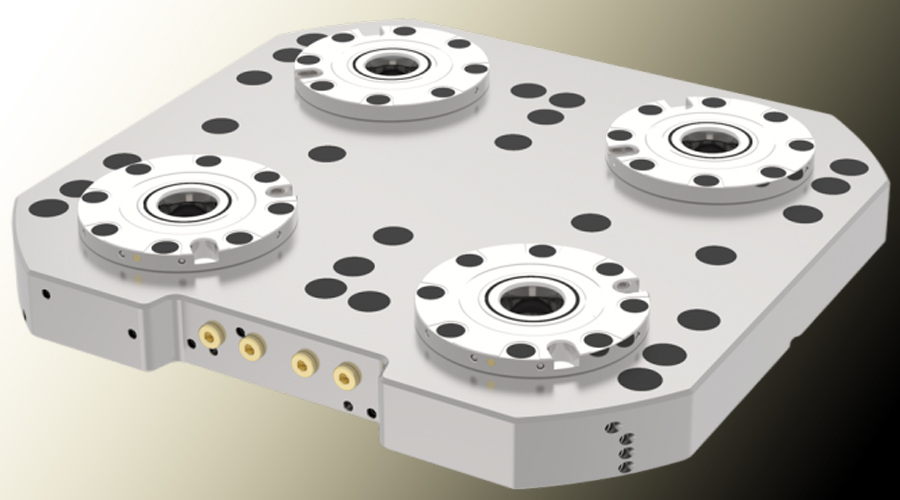

We are Manufacturer, Supplier, Exporter, Dealer, Services Provider of O Point Systems, Mechanical O Point Clamping Systems, 0 (Zero) Point Clamping Systems from Satara, Maharashtra, India.

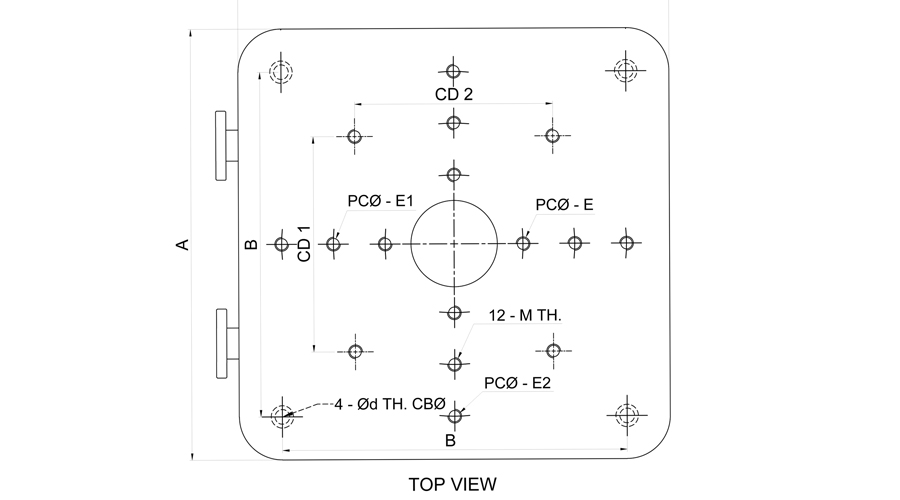

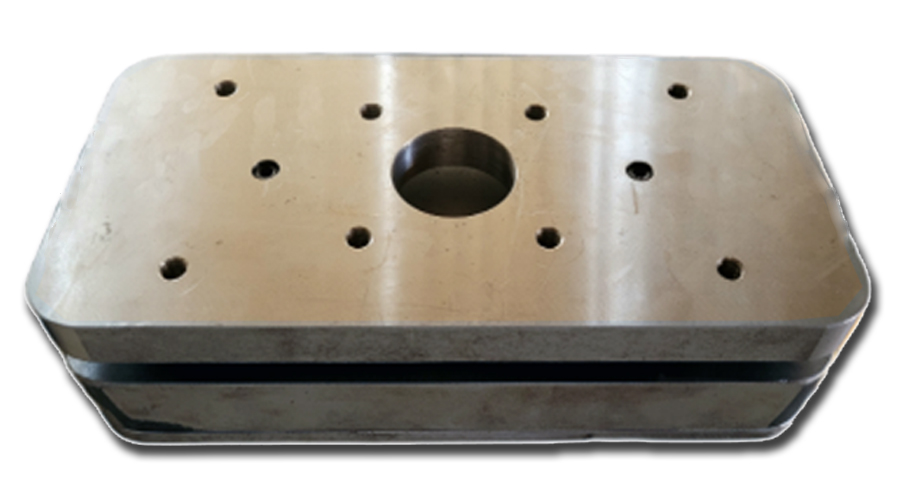

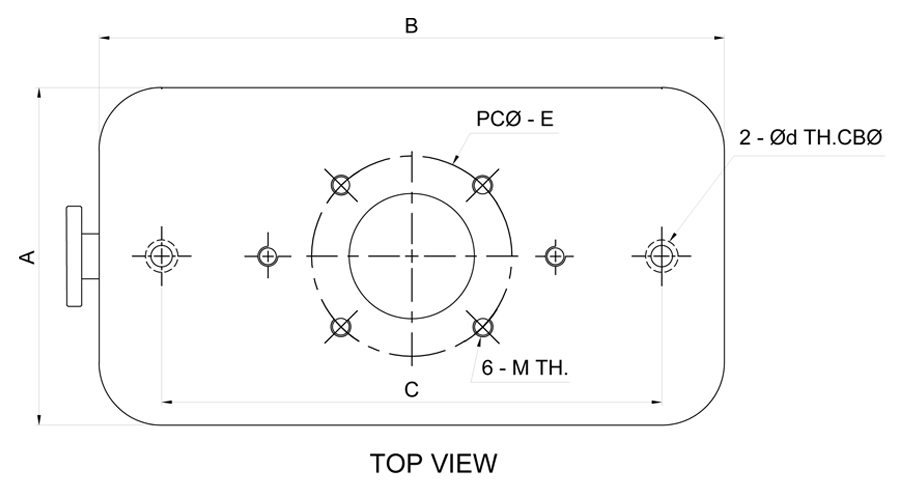

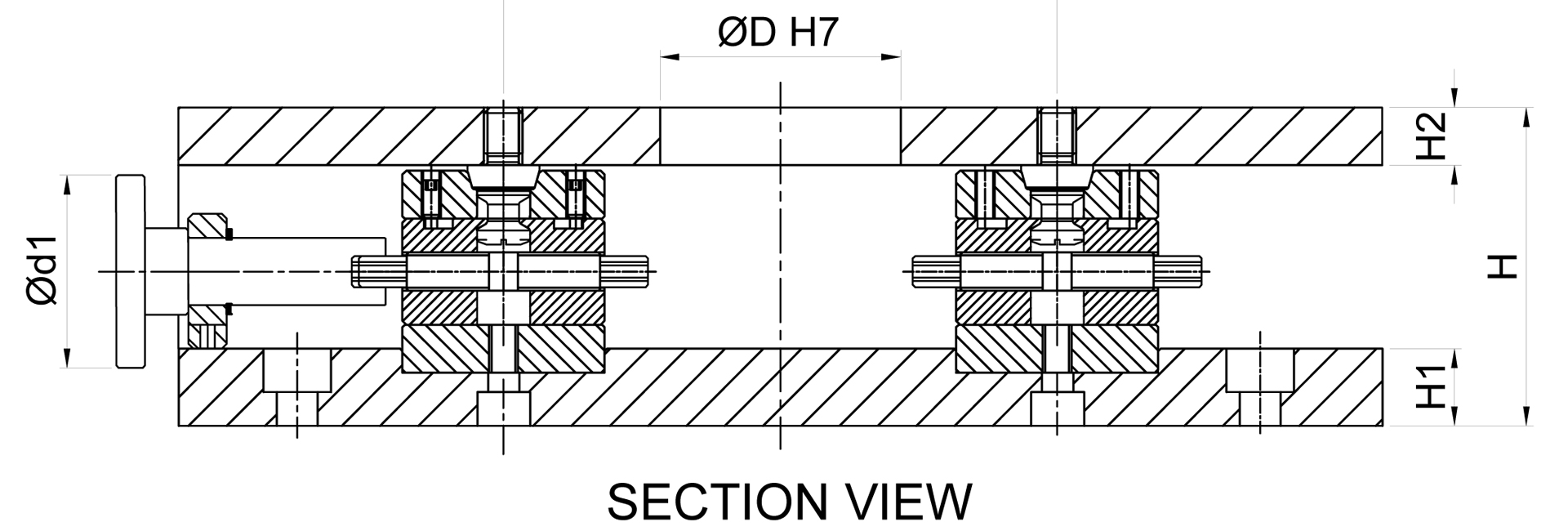

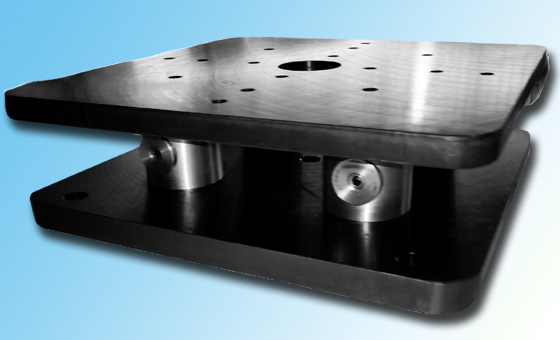

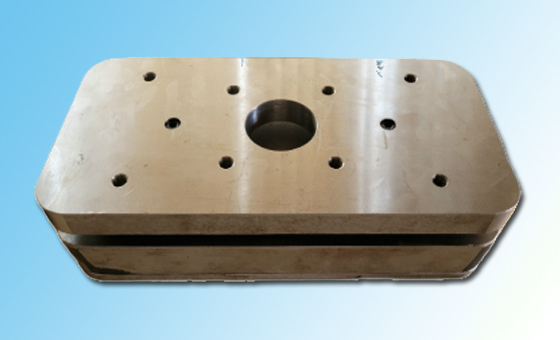

Mechanical 'O Point' Clamping Systems allows quick change fixturing with 0.005mm locating repeatability on CNC machining centres. Quick locating and clamping reduce fixture set up time by eliminating operations such as positioning, centering and fixing with screws. This mechanical Clamping Systems holds fixture plates in different sizes by changing the mounting position.

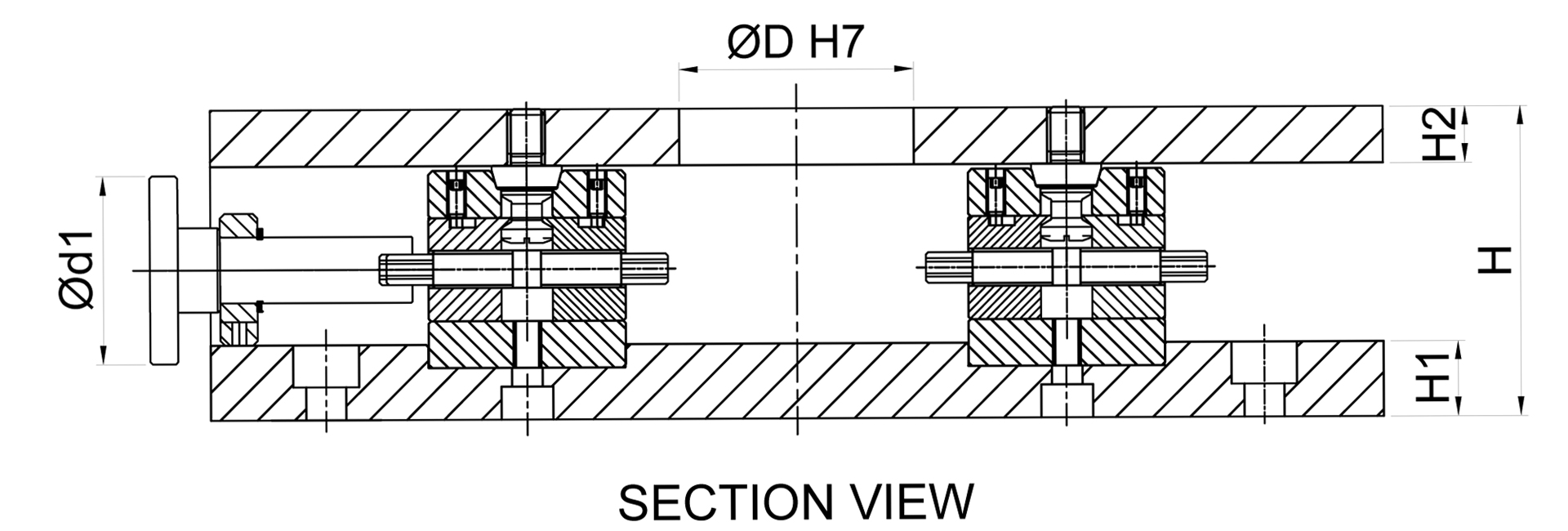

Clamping Our Mechanical 'O Point' Clamping Systems enables you to completely machine a workpiece in one setup, significantly reducing setup time and fixturing costs. With a few quick turns of a wrench, 'O Point' clamping modules locate, support, and securely clamp the workpiece from underneath, providing full machining access to 5 sides.

Clamping modules can be mounted exactly where required, anywhere on the fixture plate. These modules fit perfectly on all modular tooling plates and blocks, but can also be used with non-modular tooling. Clamping modules elevate the workpiece for machine-spindle clearance, and are stackable for extra height.

Pull-down studs must be fastened to the underside of the workpiece. Most setups require one zero-point stud (for primary two-axis location), one diamond stud (for single-axis location), and one or more floating studs (for additional support and clamping without location).