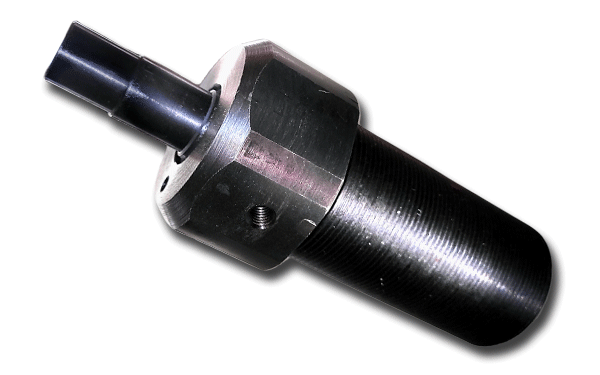

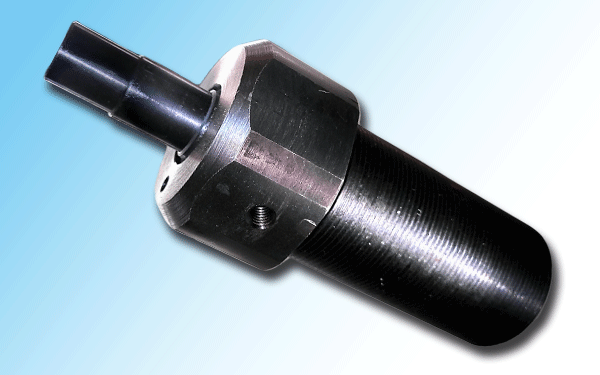

We are Manufacturer, Supplier, Exporter, Dealer, Services Provider of Push Pull Cylinders from Satara, Maharashtra, India.

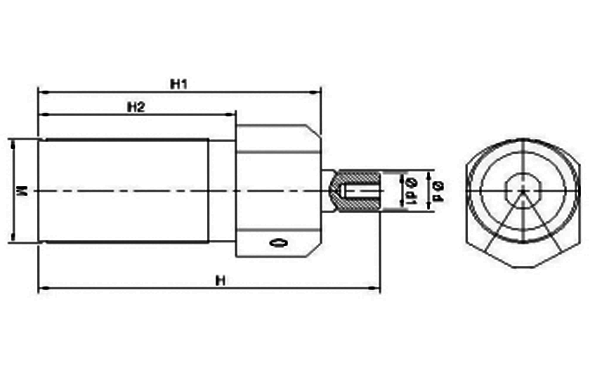

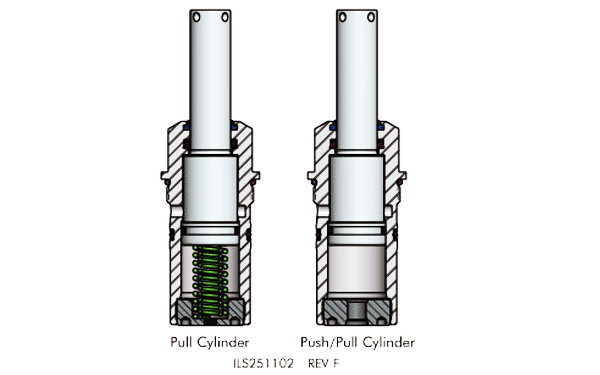

Push-Pull cylinders are sturdy, simple to mount in any position, very compact in construction. These cylinders to be mounted through thread body for precise alignment, adjustment and hydraulically operated. These cylinders are available in single acting with spring force return and double acting type with hydraulic return. Available in various capacity and sizes suitable for required application. The design is innovative and simple constructed with alloy steel and blakodised for surface protection and long life.

- Special wiper seals to keep chips and contaminants out.

- Alloy steel plungers run longer with less wear than other producers.

- Vent port gives the cylinder a place to breathe and over run.

- Blackodising on the cylinder bodies helps prevent scoring and scratching.

- Proprietary seal designs reduce leakage and increase seal life for longer lasting.

- No special mounting hardware required, secure these cylinders by bolting in place.

- Adjustable force capacity, just vary the hydraulic pressure.

- Extended piston provides a simple device for actuating clamping mechanisms.

- Threaded plunger allow the attachment of custom or to use of bolts to pull "C" washers.

- Specially designed springs run longer and require less maintenance