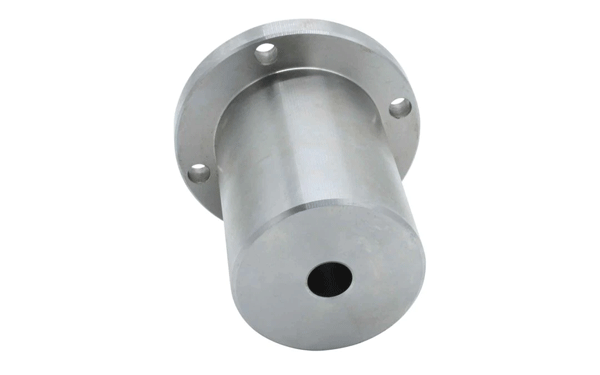

We are Manufacturer, Supplier, Exporter, Dealer, Services Provider of Clamping Cylinders from Satara, Maharashtra, India.

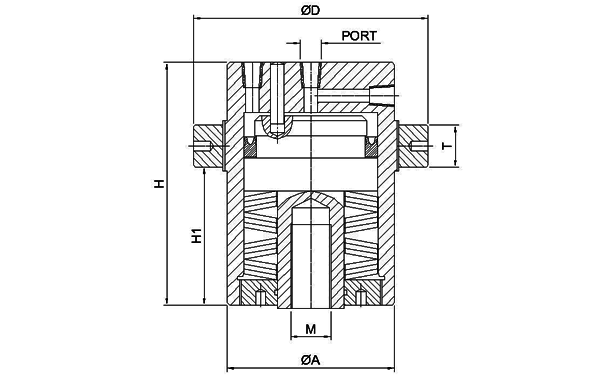

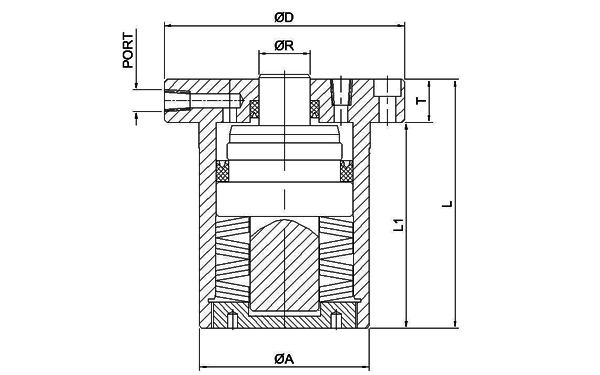

Hydro-mechanical spring clamping pistons are working with interaction of mechanical and hydraulic systems. The clamping force is applied through preloaded disk spring stack. The pistons are loaded with spring clamping, the hydraulic pressure is required only for the release of spring force. Required movement for the thrust pin is lifting. This system guarantees the greatest reliability because the clamping force is maintained fully independent of the oil pressure or leak-losses. Due to the short operating time the hydraulic system is cost effective. The clamping cylinders provide sturdy and reliable Clamping Systems, that can be used where the sliding or movable machine parts need to be clamped or locked temporarily. Other applications are fixtures for workpiece or tool clamping.

The piston thrust is developed by the disk spring stack. The spring stack is compressed with increasing oil pressure the spring force increases. Under pressure, the corresponding nominal clamping force is reached as a reaction force of the disk spring stack. To release the thrust, a higher hydraulic pressure is required, which, up to a maximum value, is proportional to the release stroke. The setting pressure is required only for precise force adjustment during initial installation. During the actual operating cycle, the cylinders are at release pressure.

- Mechanical clamping

- Hydraulic releasing

- High operational safety

- Leak-proof construction

- Robust design

- Spring Clamping Systems

- Mounting position universal

- Economical clamping solution.

- Clamping Force - 25 to 100 Kn.

- Operating Pressure - 150 bars.

- Maximum Pressure - 450 Bars.

- Operating Stroke - 1.5 to 2.00 mm

- Product Weight - 2.5 to 25 Kg.

- Oil Flow required - 2 to 15 CuCm.

- Temperature range: - 30 - 100°C

To operate a hydraulic unit is needed which should be equipped with a manometer, a pressure cut-off valve, a solenoid valve and a pressure switch unit fill the cylinders and lines at low pressure and bleed (products are supplied without oil) increase system pressure to required pressure, align cylinder using the ring guide nut, setscrews or fitting discs until the thrust piston or the clamp is free from play, fasten thrust piston with screws or secure the ring guide nut on the clamping cylinder release system pressure; set release pressure for the required release stroke; check the release stroke and adjust if necessary