Operating Operating Principle

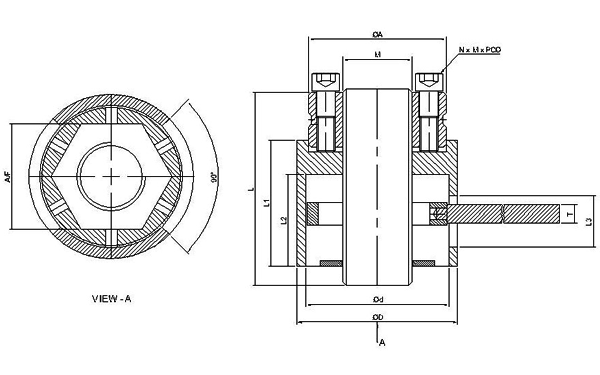

Mechanical Tensioners are designed as direct replacements for conventional nuts and bolts. Mechanical Tensioners can be replaced to a new or existing bolt, stud, threaded rod or shaft. The main thread serves to position the tensioner on the bolt or stud against the load-bearing surface through the pressure washer. Once it is positioned, actual tensioning of the bolt or stud is accomplished with simple hand tools by applying the small torque to the jack-bolts which encircle the main bolt. The jack bolts transfer the preload evenly into the main bolt and, consequently, on to the joint. The main bolt is tightened in pure tension without any torque generation.

By tightening the jack-bolts, a heavy axial force is generated. This force is directed against a pressure washer. Jack-bolts have a very small friction diameter and can therefore create a high thrust force with relatively little torque input. The loads are transferred through the nut body which is positioned on the main bolt by hand rotation. br

A pressure washer is used to transfer the force while protecting the flange face. The axial force of jack-bolts and the opposite reaction force of the main bolt head create a strong clamping force on the flange. The axial force from the jack-bolt creates an equally strong reaction force in the main bolt. You can trust our products, we guarantee that our mechanical tensioner products will stay in place and fulfil their function for the entire lifetime of the bolted connection.

Assembly / Mounting

Clean and degrease the threads of the tensioner nut and screws. If the components are mounted with several clamping nuts (flange connections), each of the following steps on all clamping nuts must be completed before the next step follows. The clamping screws in the clamping nut must not come out of the pressure side. Shift the washer onto the screw up to the contact surface of the adjacent component. Afterwards screw on the nut and hand-tighten it.

All components must be superimposed without any gap

Afterwards turn back the nut until there is a gap of 1 - 2 mm. Hand-tighten the pressure screws marked. Tighten these screws at half the tightening torque according to table and afterwards at the full tightening torque according to table. Now tighten all pressure screws one after another and with several revolutions until all screws have achieved the full tightening torque. The pressure screws must not be rest on the heads after assembly

Assembly / Mounting

Untighten the pressure screws of the clamping nut with several revolutions by a quarter revolution until all screws are released from tension. If components with several clamping nuts are disassembled (flange connections), each revolution must be performed one after the other on every clamping nut before the next revolution is started with.

The clamping nuts must not be disassembled individually.

Do not relieve and unscrew individual pressure screws completely in any case.

Unscrew the clamping nut and remove the washer.

Maintenance and service

The ‘PRSverse’ clamping nuts have to be inspected after 500 hours of operation for the first time and afterwards at least once a year. Please pay special attention to the condition of the screwing. After start-up of the machine the tightening torques of the clamping nuts' pressure screws have to be inspected during usual maintenance intervals

Disposal

In respect of environmental protection we would ask you to dispose of the packaging or products on termination of their service life in accordance with the legal regulations and standards that apply, respectively. All components of the clamping nut consist of metal. Any metal components have to be cleaned and disposed of as scrap metal.