We are Manufacturer, Supplier, Exporter, Dealer, Services Provider of Mechanical Tensioners from Satara, Maharashtra, India.

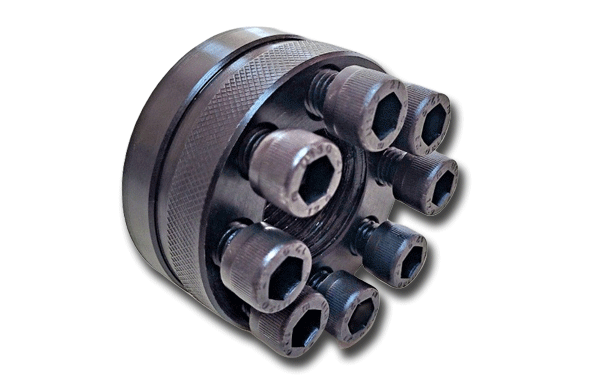

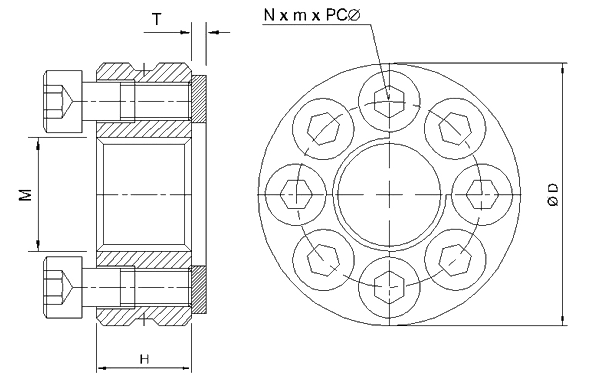

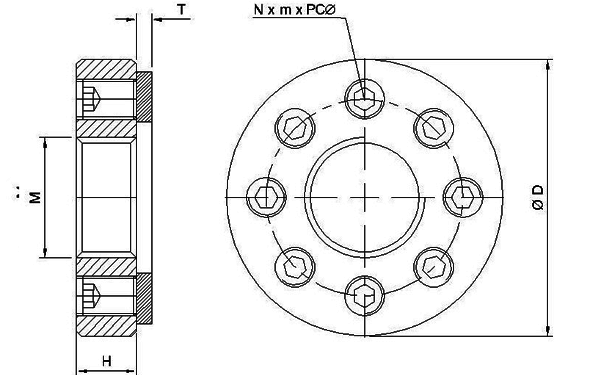

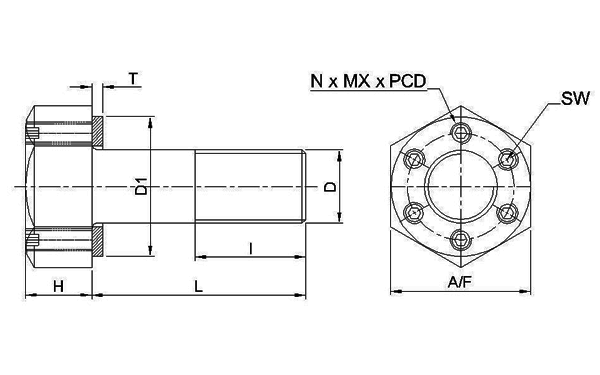

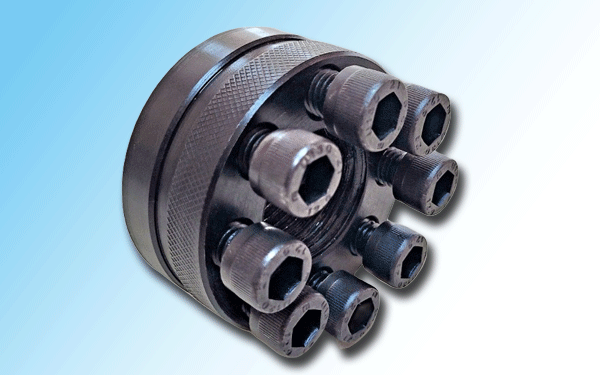

In a world of heavy industry, where large machines and equipment build and shape our world. No one should ever have to question the integrity of critical bolted connections. PRSverse mechanical nuts and bolts tensioners use the multi-jack principle for bolt tension. This is proven technology used for successful installations. Mechanical Tensioners are easy to work with and provide a mechanical advantage with their unique design, which divides the load among multiple sm all jack bolts. Correctly installed, connections are reliable, stay tight indefinitely and disassemble easily for planned maintenance. Even the largest nut and bolts are safe and can be installed or removed by a single worker with ordinary hand tools. These solutions to solve the bolting challenges.

The pressure vessel is a one example where millions of Mechanical Tensioners are used to secure bolts on the critical applications.