We are Manufacturer, Supplier, Exporter, Dealer, Services Provider of Precision Inspection Vises (Vices) from Satara, Maharashtra, India.

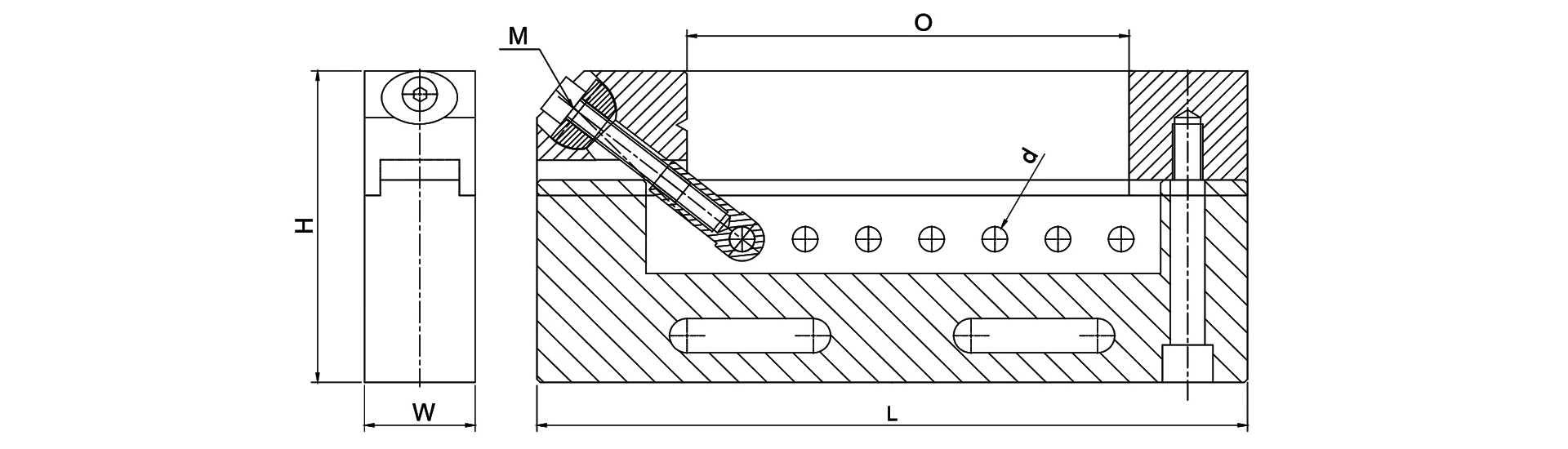

All Vise surfaces are precision ground. The movable jaw is slightly narrow than the base enabling the vises to be used on either side in addition to the base. Clamping and releasing is through a threaded spindle with precision cut threads for smooth operation. Vise spindle moves in a specially designed gun metal bush which reduces wear thus enhancing the life of the vise. Fix Jaw side threaded for clamp support.

Used in tool manufacturing, on grinding, milling, and jig boring machines for measurement an inspection work and in manufacturing processes that require highest standards of clamping accuracy.

Manufactured from Selected alloy Steel, these solid one piece vises are fully hardened (25-32 HRC) and tempered to ensure stability and durability. Accuracy: Parallelism: 0.015 max. (15 Microns), perpendicular: 0.015 max (15 Microns)