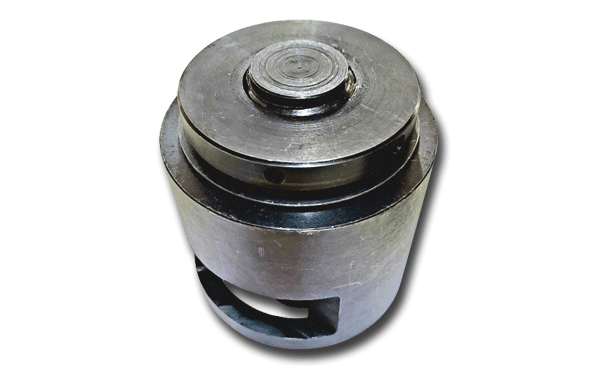

Operating Principle

Hydraulic tensioners nut develops a load directly proportional to the oil pressure, this can be accurately controlled and because it is developed hydraulically it is evenly applied. Multiple nuts can be connected with hoses for simultaneous operation allowing all bolts in a joint to be evenly loaded to the same high and accurate pre-load.

When oil pressure is applied, the joint is compressed and the bolt stretches, this produces a gap between the body of the nut and the piston. Depending on the type of nut, either shims are inserted into the gap or a locking collar on the piston is turned. When the hydraulic pressure is released, the load is transferred onto the shims or the locking collar to retain the load

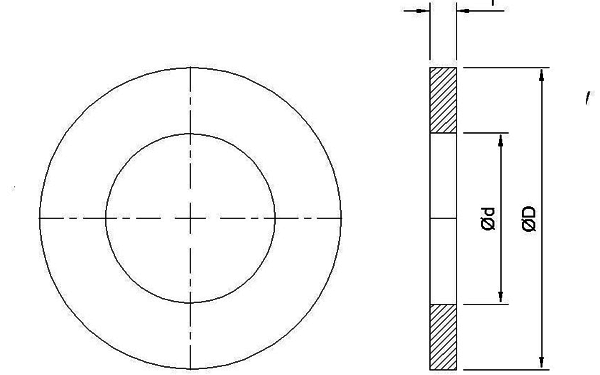

The Hydraulic Nuts is self-aligning while under pressure and misalignment or flange rotation will produce a variation in the gap between the nut body and the piston. In the case of shim type nuts, tapered shims can be made and fitted to eliminate the effects of misalignment and flange rotation. In the case of collar type nuts, a spherical washer would need to be fitted under the Hydraulic Nuts.

Achieving a bolt pre-load which is in excess of the working load and eliminating bending and torsional stresses greatly improves the fatigue performance of the bolt. The internal jacking system is not under any pressure when the nut installation is complete and so does not deteriorate when the nut is in service providing it is not exposed to high radiation doses or elevated temperatures.

How It Works

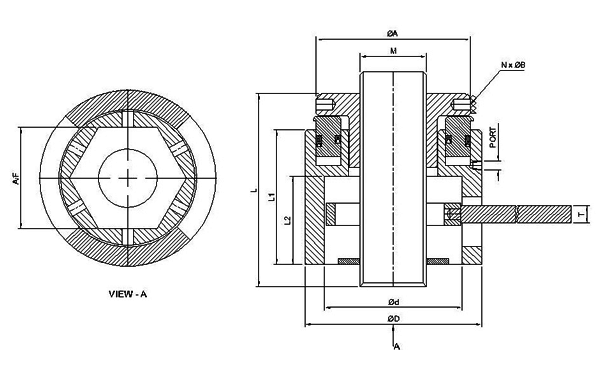

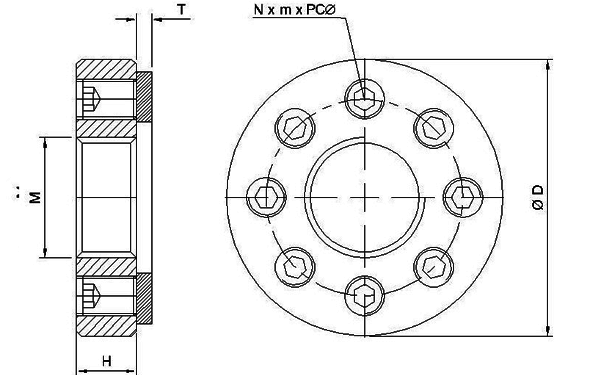

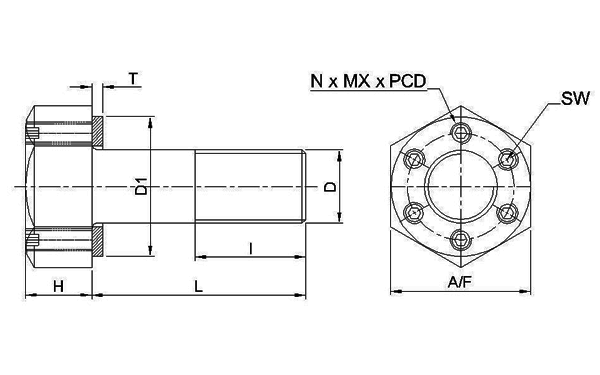

By pressurizing the hydraulic cylinder, a heavy axial force is generated. This force is directed against a hardened washer. hydraulic cylinder generated only axial thrust force. The loads are transferred through the nut body which is positioned on the main thread. A hardened washer is used to transfer the force while protecting the flange face. The axial force of hydraulic cylinder and the opposite reaction force of the main bolt head create a strong clamping force on the flange. The axial force from the hydraulic cylinder creates an equally strong reaction force in the main bolt. You can trust our products; we guarantee that our hydraulic tensioner products will stay in place and fulfill their function for the entire lifetime of the bolted connection.