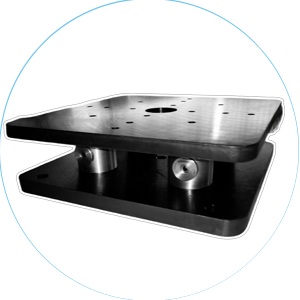

We are Manufacturer, Supplier, Exporter, Dealer, Services Provider, of Collet Mandrel System from Satara, Maharashtra, India.

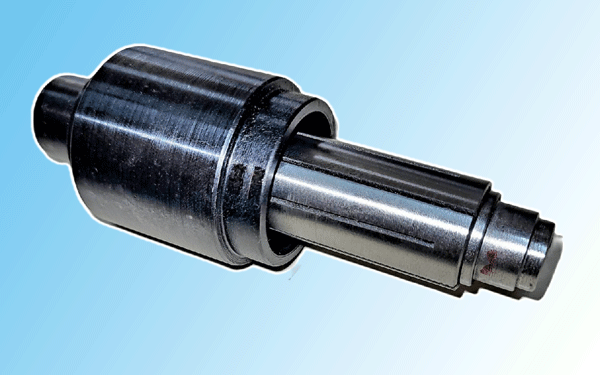

For clamping, the Taper Collet is pushed against the centre mandrel body and radially expands over the cone of base body. The component is centred, pressed against the backstop and aligned flush. The cylindrical form of the component bore in the clamping area has to be smaller than the tolerance class IT7, independent of the component bore tolerance.

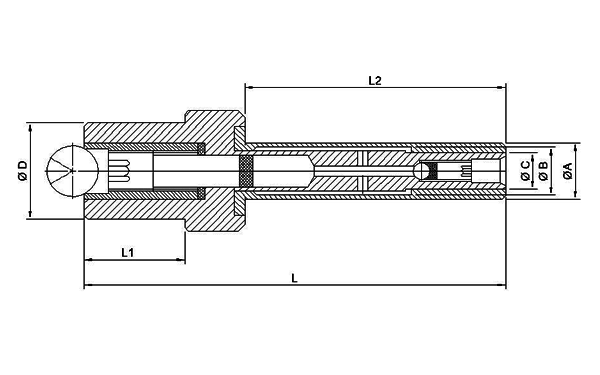

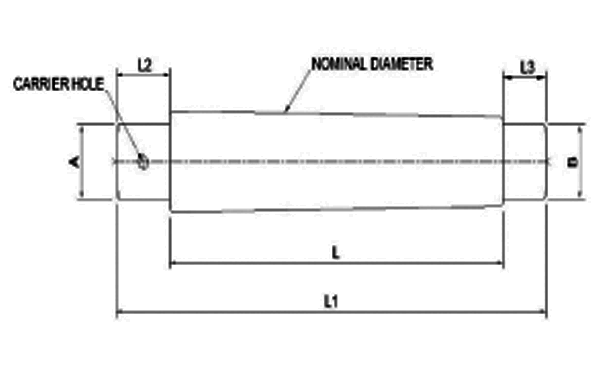

The Taper Collet Centre Mandrel consists of a centre mandrel body and a Taper Collet with a clamping nut. The Taper Collet Centre Mandrel is mounted between the centring tips. The Taper Collet is activated by turning the clamping nut.

- For clamping diameters from 11,9 mm to 132 mm

- High true running accuracy ≤ 0,01 mm

- Permissible component tolerance up to IT15

- Pull-back against external backstop ring by the customer

- For thin-walled or solid components

- For hand clamping